Elevating your material handling processes to new standards is a primary goal for many businesses. Enter bridge cranes, the powerful workhorses designed to optimize workflows within plants. By implementing EOT cranes, companies can leverage space, boost efficiency, and lower operational costs.

- These cranes feature versatile lifting ranges, customized to the individual needs of each sector.

- Advanced controls| are increasingly being integrated into EOT cranes, further boosting precision and risk mitigation.

- In conclusion, EOT cranes represent a cost-effective investment for companies seeking to optimize their material handling systems.

Powerful Jib Crane Arrangements for Your Workspace

A versatile jib crane can be a valuable resource for any workspace, offering a wide range of functions. These cranes are renowned for their ability to seamlessly move heavy loads in confined spaces. With adjustable reach and lifting capacities, jib cranes can be tailored to meet the unique requirements of various industries, including manufacturing, construction, and warehousing.

- Evaluate a jib crane if you regularly handle heavy materials.

- Jib cranes can enhance your output by accelerating material handling tasks.

- Acquiring in a jib crane can greatly improve workplace safety by reducing manual lifting efforts.

Automated Khoya Making: Precision and Efficiency

The rise in automated khoya making has brought about a new era to the dairy industry.

Khoya, a rich dairy concentrate, is essential in many traditional South Asian desserts and confectioneries. Automated systems guarantee precise control over the production, resulting towards consistently high-quality khoya.

This accuracy allows manufacturers to produce khoya which meets strict requirements. Moreover, automation enhances efficiency by minimizing manual labor and enhancing the production flow.

- Automated systems utilize advanced sensors and controls to monitor and adjust settings throughout the khoya-making procedure.

- This brings to uniform product quality and lowers the risk with human error.

Consequently, automated khoya making offers numerous advantages for both manufacturers and consumers.

Producing Excellence: High-Performance Bakery Ovens

Achieving unparalleled flavors in your bakery relies heavily on the efficiency of your ovens. High-performance bakery ovens provide precise temperature control, rapid heating times, and even distribution of heat for consistently delicious baked goods. Opting in a top-tier oven can dramatically improve your productivity while optimizing the overall taste of your creations.

- Regarding artisan breads to delicate pastries, these ovens accommodate a wide range of baking needs.

Whether you're a small shop or a large-scale operation, a high-performance oven is an critical acquisition for achieving true baking excellence.

Revolutionizing the Baking Process with Modern Oven Technology

Gone are the days of figuring out baking times and temperatures based on intuition alone. Modern oven technology is redefining the way we bake, offering a plethora of tools that make the process simpler. With smart controls, ovens can now precisely regulate temperature and time, ensuring reliable results every time.

- Amenities like convection cooking, rapid preheating, and steam injection allow bakers to achieve delicious outcomes with minimal effort.

- Some ovens even offer built-in sensors that measure the advancement of your baking, notifying you when it's done.

This advancements have enabled bakers of all levels to produce delicious creations with newfound simplicity. The future of baking is here, and it's more innovative than ever before.

Improving Production with Automated Khoya Machines

The dairy industry is constantly seeking ways to increase production efficiency. One such innovation is the adoption of automated khoya machines. These machines simplify the process of manufacturing khoya, a crucial material in various Asian dishes. By reducing manual labor and improving precision, automated khoya read more machines offer significant benefits for manufacturers.

- Enhanced Production Output

- Minimized Labor Costs

- Improved Khoya Quality and Consistency

- Enhanced Operational Efficiency

The adoption of automated khoya machines enables businesses to grow their operations and satisfy the growing demand for khoya. Furthermore, these machines contribute in enhancing food safety by minimizing human contact during production.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Tatyana Ali Then & Now!

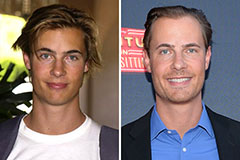

Tatyana Ali Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!